|

Introduction:

The enzyme β-galactosidase (β-gal) plays an

important role in cellular metabolism by breaking down lactose into

glucose and galactose (Figure

1), important fuels for the cells. In E. Coli the

lacZ gene produces β-gal and is often used as a marker

for gene expression. In this study, we will be measuring enzyme

kinetics of β-gal indirectly using a lactose analog, o-nitrophenyl-β-galactopyranoside

(ONPG) which is cleaved by β-gal to o-nitrophenyl-(ONP) which

has a different absorbance and can observed by eye. Quantitation is

achieved using a spectral photometer. Enzyme kinetics will be

calculated using the following equation:

Aims:

1. Verify experimentally if β-Galactosidase kinetics are linear

2. Determine rate constants and conversion of ONPG to ONP by β-Gal

3. Determine molar extinction coefficient for ONP experimentally

Methods:

1. Calculate molar extinction constant from

Fowler & Zabin (PNAS 1977):

# of AA in β-galactosidase

Extinction coefficient @ 280 (mol/cm)

38 tryptophan

5690

31 tyrosines

1280

16 cystines (half-cystines) 120

From equation 1

in

Gill & von Hippel (Analy Biochem, 1989):

Extinction

coefficient = 4x[38(5690) + 31(2180) + 16(120)]M-1cm-1

2. Dilute ONPG and β-Galactosidase

in phosphate buffer and Z buffer, respectively:

Phosphate buffer:

1.61g Na2HPO4-7H2O, 0.55g NaH2PO4-H2O

in 100mL DD-H2O and adjust pH to 7.0

Z-buffer: 0.8g Na2HPO4-7H2O,

0.28g NaH2PO4-H2O, 0.5mL of 1M KCl,

0.05ml of 1M MgSO4,

0.135ml β-mercaptoethanol, adjust pH to 7.0 and store at

4C.

In order to plot the

linear kinetics, we diluted β-gal at 6 different

concentrations. To do this over multiple trials,

troughs were filled according to the table below:

Well Row

Conc(units/ml) Measurement

D1 33 84 ul of 330

u/ml beta-gal

756 ul of z-buffer

D2

16.5 42 ul of beta

798 ul

of z

D3

8.25 21 ul of beta

819 ul

of z

D4

4.125 10.5 ul of beta

829.5 ul

of z

D5

2.1 5.25 ul of beta

835 ul

of z

D6

1 2.63 ul of beta

837 ul

of z

210 ul of 4 mg/ml

phosphate buffer + ONPG per trough

Using a multichannel pipette, rows B-F of the of the plate is filled

according to the diagram below:

Rows B-F were filled

with 140 ml from each trough

B-E were then filled

with 35ml of ONPG+phosphate buffer

F was filled with

just 35 ml of buffer, no ONPG to serve as a control

B8 was filled with

140 ml of z-buffer and 35 ml of ONPG.

3. MeasureOD at 420nm using an automated plate

reader, data was acquired every 15 seconds for 60 minutes.

4. An addition dilution at 100x was acquired:

1)

175/7 = 25 ul out of each well in row D and placed into row G

2)

Added 150 ul of buffer to each well in row G to dilute by

100x

3)

Took 25 ul out of each well in row E to row H

4)

In row H added 150 ul of buffer to each well to dilute

controls by 100x

5)

Took 25 ul out of B8 and added it to C8

6)

Added 150 ul of buffer to dilute negative control by 100x

7)

Ran in spectrophotometer at 300 nm to 800 nm in 2 nm steps

5. In order to quantify β-galactosidase,

we must denature the protein and obtain a proper measurement of the

residues:

1)

Take 18 ul of β-galactosidase in eppedorf and placed it in

D8

2)

Added 162 ul of Gaunidinium HCl to dilute it by 10x

3)

Added 150 ul of Gaunidinium HCl and 25 ul of z-bufer in F8 as

a control

4)

Acquired data in spectrophotometer at fixed wavelength of

280nm

5)

Absorption measured in D8 = 1.6061, F8 = 1.4758

6)

Measured well size = 6.6 mm=0.66cm

7)

ONPG concentration:

6. Using calipers, the well

heigh was measured, this is necessary for the following ONP

extinction coefficient calculations:

Results:

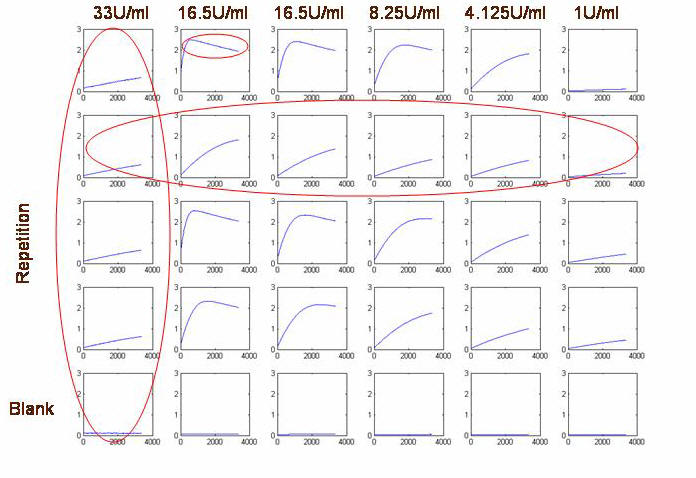

The OD measurements

for wells B-F are shown below:

As seen in kinetic

reaction plot, there is degradation in ONP corresponding to

approximately 0.4 OD units. Since this degradation is in the

non-linear absorbance regime, we cannot extrapolate a constant to

add. This experiment can be performed again with the same enzyme and

substrate concentration, and stopped before degradation occurs,

since we now know the timescale.

Error estimate: there

may be deviations in the height of the well due to pippeting errors.

:

Solving for K+:

After solving the

differential equations we get the term:

The literature figure

for  =3500 =3500 .[1] .[1]

The Literature states that Kcat =

480 [2].

As we can see, the only set of parameters fitting the literature are

the averages of the small slopes and the literature cited extinction

coefficient.

Slopes for the graphs starting with 33u/ml(left)

ending with 1 u/ml(right):

0.0098 0.2104 0.1268 0.0684

0.0243 0.0036

After modeling differential equations:

Slope: 0.5853 0.6243 0.5482 0.3795

0.2349 0.1251

|